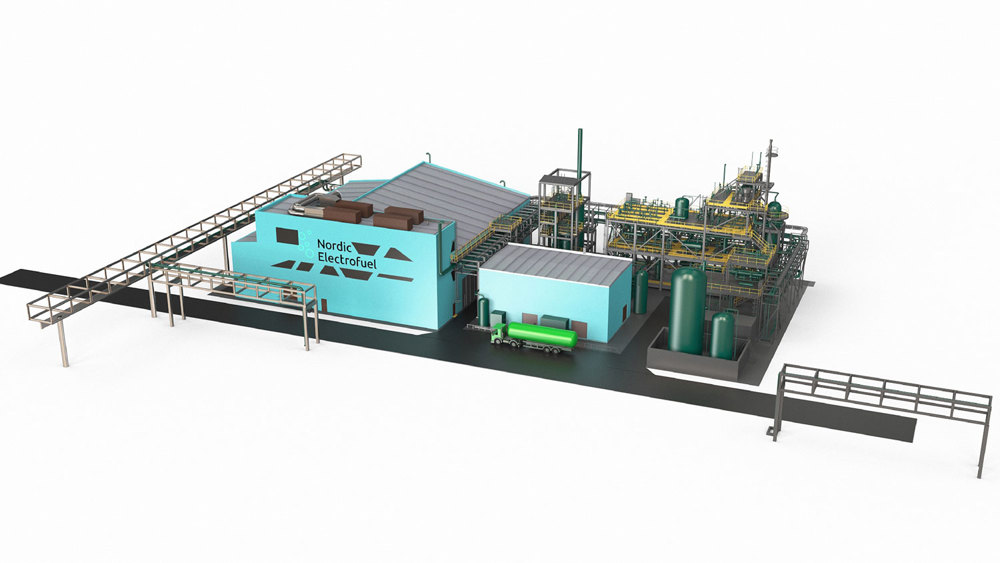

Production of 10 million liters of climate-neutral fuel is planned to start in 2024.

Start construction in 2022

Victor Dias, Nordic Electrofuel's plant manager, and his colleagues are in full swing with preparations for the start of construction.

"We plan to start construction activities at this plot in 2022", says Victor Dias. He is the newly appointed factory manager, and will now spend the next couple of years building the plant that will produce e-fuel. Production start is planned for 2024.

First in Norway

"We are constructing the first factory in Norway, the first on an industrial scale and perhaps the first in the world", says Victor Dias proudly. "Here we will produce climate-friendly e-fuel, synthetic fuel made from CO / CO2, water and electricity."

There are e-fuel plants for the production of e-methanol elsewhere in the world, but the plant that Nordic Electrofuel plans to build at Herøya will be the first industrial plant in the world for the production of hydrocarbon-based e-fuel. This fuel is well suited as an aviation fuel.

Dias talks about the great benefits of the fuel that can be filled directly into the tank in machines, trucks and planes without the need to rebuild equipment and engines or new infrastructure. He also talks about the benefits of establishing the facility in Herøya Industrial Park.

Leading the way

According to Nordic Electrofuel, e-fuel can reduce CO2 emissions by 85 percent compared to today's fossil fuels.

"All companies now work with green industry, we do too. We are leading the way," says Dias enthusiastically. "Nordic Electrofuel has developed groundbreaking new technology together with, among others, researchers at NTNU. This technology will work in the facility on Herøya."

Dias makes no secret of the fact that they hope to obtain support from ENOVA for the production plant, which is estimated to cost more than NOK 1.5 billion.

Herøya Industripark AS, the industry incubator Proventia at Herøya, and other players also actively contribute with technological cutting-edge expertise and a network for the establishment to be successful at Herøya.

Synergies in the industrial park

Dias points to many synergies and opportunities that can be developed with several players in Herøya Industrial Park, including the purchase and sale of hydrogen. He knows the industrial environment well after several years of experience from starting up and operating factories, first from REC Solar and most recently as operations manager at RHI Normag.

Great ambitions for the future

Nordic Electrofuel's first plant at Herøya is a demonstration plant on an industrial scale. In the long term, the ambitions are to build a larger plant for the production of 200 million liters of fuel, and by 2030, produce 1 trillion liters of synthetic fuel in Norway.

Facts about the production facility at Herøya

- Suppliers: Aker Solution supplies Front End Engineering in close collaboration with ARVOS GmbH Schmidtsche Schack and Emerging Fuel Technology. Bilfinger has also been a good contributor with designs for connecting auxiliary systems at Herøya.

- Raw materials: CO/CO2, water and electricity.

- Nordic Electrofuel and Eramet Norway enter into agreement on CO2 from furnace gas for new climate-neutral green fuel in 2021.

- Production capacity: 10 million liters of e-fuel annually.

- Manning operations: 20-23 persons on shift

04. January 2022